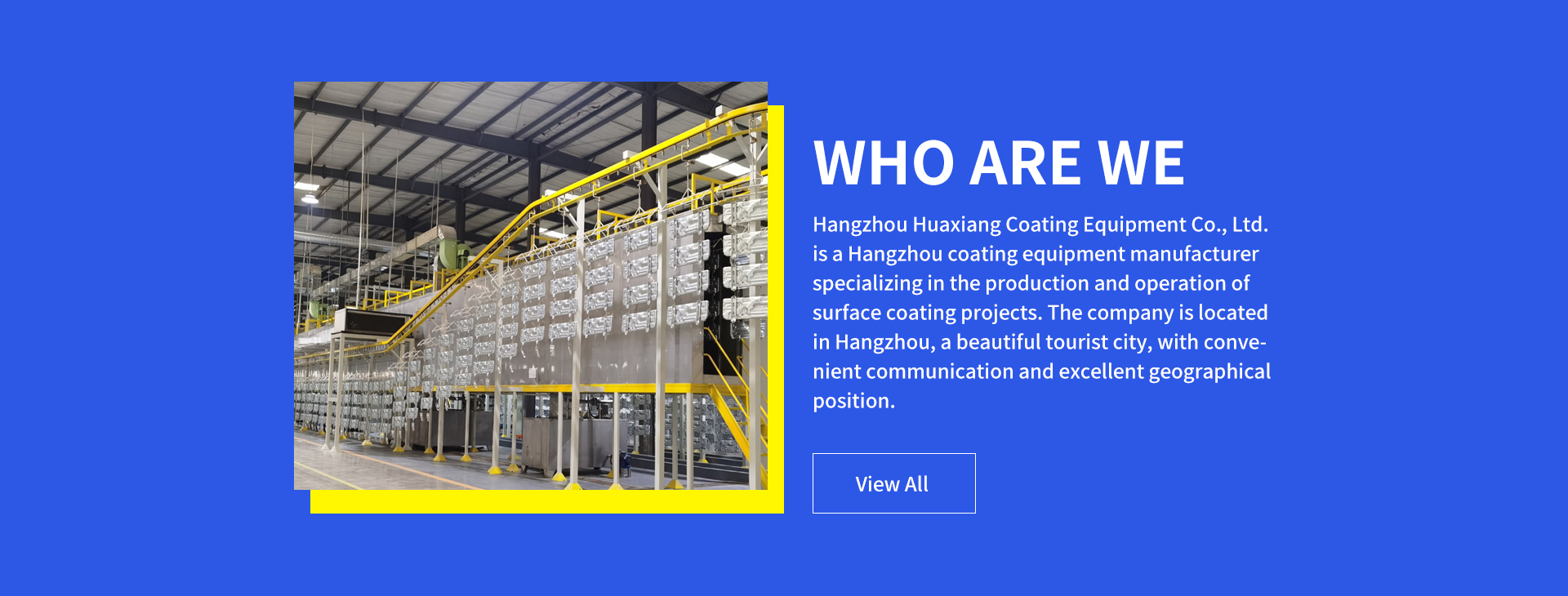

1. Introduction to Industrial Powder Coating Ovens

Industrial Powder Coating Ovens are critical for curing powder-coated surfaces, ensuring durability and high-quality finishes. These ovens feature an insulated chamber, advanced heating elements, precise control systems, and efficient ventilation. The chamber is designed to withstand extreme temperatures, while the heating system ensures uniform heat distribution. Control panels allow operators to set and monitor curing parameters, and ventilation systems maintain air quality by removing harmful fumes.

2. Key Applications of Industrial Powder Coating Ovens

Industrial Powder Coating Ovens are indispensable in industries like automotive, aerospace, furniture, and electronics. They are used to coat metal parts, appliances, and machinery components, providing finishes resistant to corrosion, scratches, and UV damage. Their versatility makes them suitable for both small workshops and large-scale manufacturing facilities.

3. Pricing Factors for Industrial Powder Coating Ovens

The cost of Industrial Powder Coating Ovens depends on size, capacity, and features. Smaller models start around 3,000,whilelarger,custom−builtovenscanexceed50,000. Energy efficiency, temperature range, and automation capabilities also impact pricing. Investing in a high-quality oven ensures long-term reliability and cost savings.

4. Best Practices for Using Industrial Powder Coating Ovens

To achieve optimal results, preheat the oven to the recommended temperature (typically 300°F to 450°F). Ensure proper spacing of coated parts to allow even heat distribution. Monitor curing times closely to avoid over- or under-curing, which can compromise finish quality. Regular calibration of temperature controls is essential for consistent performance.

5. How to Select the Right Industrial Powder Coating Oven

When choosing an Industrial Powder Coating Oven, consider factors like size, temperature range, energy efficiency, and control features. Evaluate your production volume and material types. Opt for ovens with robust insulation, reliable heating systems, and user-friendly controls. Consulting with industry experts can help you make an informed decision.

6. Safety Measures for Industrial Powder Coating Ovens

Safety is critical when operating industrial powder coating ovens. Always wear protective gear, including heat-resistant gloves and goggles. Ensure proper ventilation to eliminate toxic fumes. Regularly inspect the oven for wear and tear, and adhere to manufacturer maintenance guidelines. Avoid overloading the oven to prevent uneven heating and potential hazards.

7. Design Efficiency of Industrial Powder Coating Ovens

Industrial powder coating ovens are designed for efficiency and durability. Insulated chambers minimize heat loss, while advanced control systems ensure precise temperature regulation. Ventilation systems are strategically placed to maintain air quality. These design features enhance performance, reduce energy consumption, and lower operational costs.

8. Frequently Asked Questions About Industrial Powder Coating Ovens

Q1: What is the optimal temperature for curing powder coatings?

A1: The optimal temperature typically ranges between 300°F and 450°F, depending on the powder material.

Q2: How can I maintain my industrial powder coating oven?

A2: Regular cleaning, inspecting heating elements, and ensuring proper ventilation are essential maintenance steps.

Q3: Are custom industrial powder coating ovens available?

A3: Yes, many manufacturers offer custom solutions tailored to specific production requirements.

Q4: What safety features should I prioritize?

A4: Look for automatic shut-off, temperature alarms, and robust ventilation systems.

Q5: How long does curing take in an industrial powder coating oven?

A5: Curing times typically range from 10 to 30 minutes, depending on the material and oven temperature.

This guide provides a detailed overview of industrial powder coating ovens, highlighting their applications, pricing, and safe operation. By following these insights, you can optimize your coating processes and achieve superior results, ensuring your operations are efficient and cost-effective.

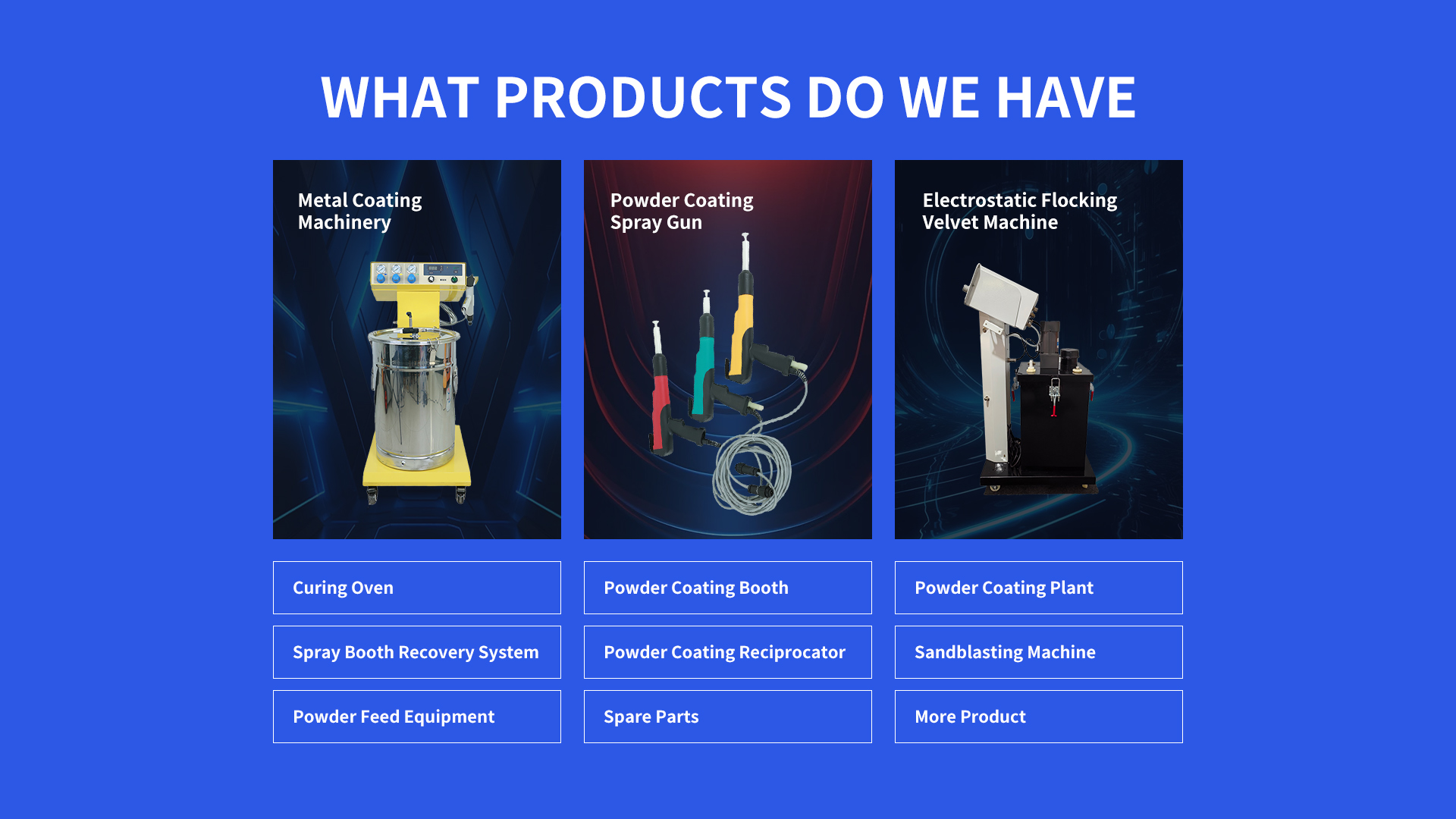

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com